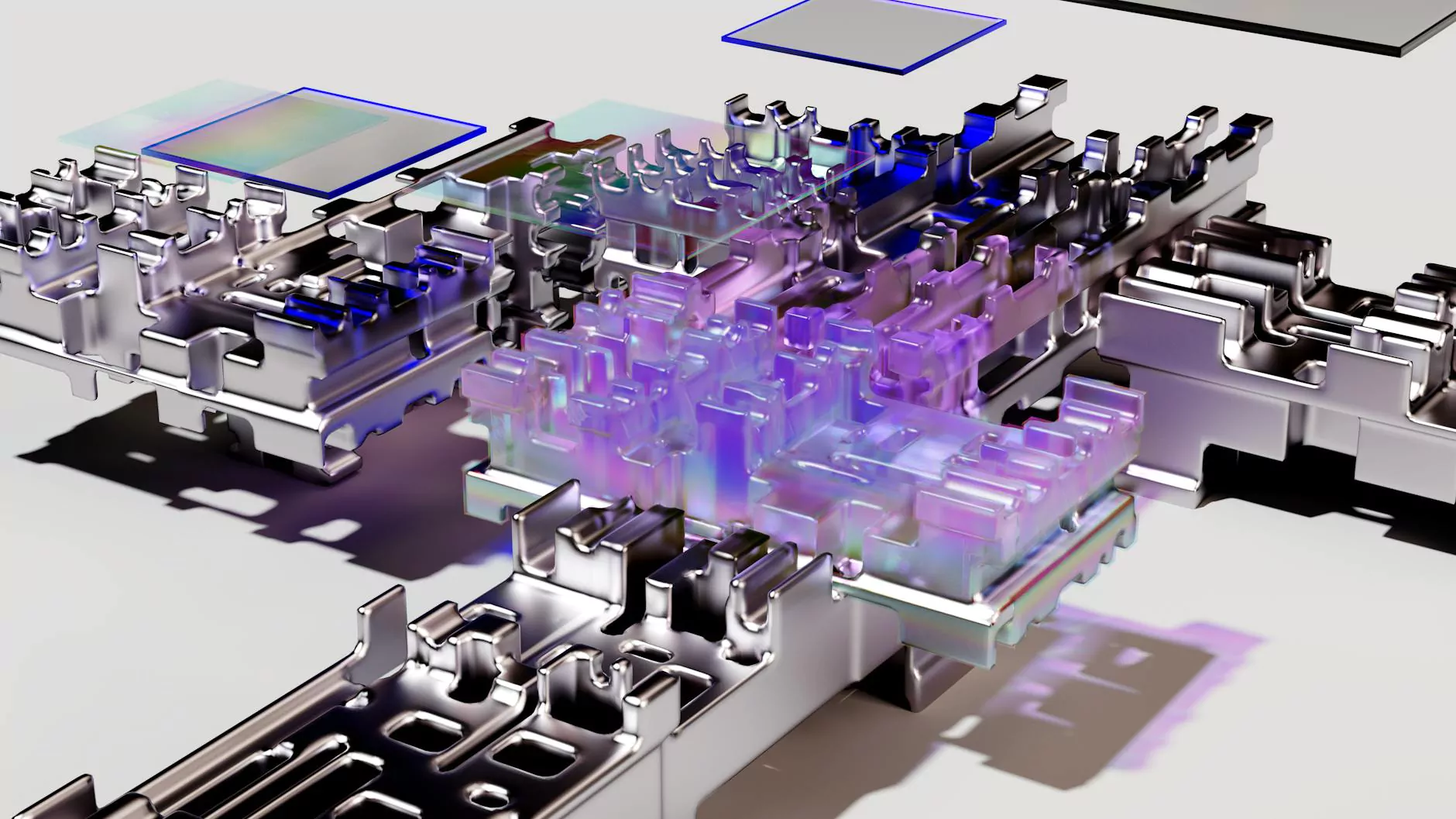

Understanding Precision Machining CNC Parts

In today's fast-paced manufacturing environment, the demand for high-quality, precise components is at an all-time high. Precision machining CNC parts are at the forefront of this demand, providing essential components for various industries, from automotive to aerospace, electronics, and beyond. As a leader in the field, DeepMould.net specializes in delivering exceptional metal fabrication solutions that meet the specific needs of our clients.

What is Precision Machining?

Precision machining is a process that involves the removal of material from a workpiece to shape it into a desired form with high accuracy. This process relies on Computer Numerical Control (CNC) technology to ensure that each cut is made with meticulous attention to detail. The benefits of precision machining CNC parts include:

- High Accuracy: CNC machining can achieve tolerances as tight as ±0.001 inches.

- Repeatability: The same part can be produced multiple times with identical specifications.

- Complex Geometries: CNC machines can create intricate designs that are challenging or impossible to achieve manually.

- Material Versatility: Various materials, including metals, plastics, and composites, can be used.

A Deep Dive into CNC Technology

Computer Numerical Control (CNC) technology has revolutionized the manufacturing sector. It utilizes computer software to control machine tools, allowing for efficient and precise production of parts. Precision machining CNC parts involves several key processes:

1. CNC Milling

CNC milling uses rotary cutters to remove material from a stationary workpiece. It is ideal for producing complex shapes and features with high precision.

2. CNC Turning

This process involves rotating a workpiece while a cutting tool removes material. CNC turning is excellent for creating cylindrical parts.

3. CNC Wire EDM

Wire Electro-Discharge Machining (EDM) uses a thin wire to cut through electrically conductive materials. It is particularly useful for intricate or delicate parts.

4. CNC Laser Cutting

Laser cutting utilizes a high-powered laser beam to cut through materials, offering high precision and minimal material waste.

Applications of Precision Machining CNC Parts

The applications of precision machining CNC parts are vast and varied. Here are some of the key industries that benefit from these services:

- Aerospace: Parts produced with extreme precision are critical for safety and performance.

- Automotive: Precision machined components are essential for engine parts, transmission systems, and more.

- Medical Devices: The medical industry requires highly accurate parts for instruments and devices.

- Electronics: CNC machining plays a crucial role in producing components for electronic devices.

Benefits of Partnering with DeepMould.net

When it comes to precision machining CNC parts, partnering with a dependable supplier like DeepMould.net makes all the difference. Here’s why:

1. Superior Quality Control

At DeepMould.net, we employ stringent quality control measures. Our team conducts regular inspections and tests to ensure each part meets established specifications.

2. Advanced Technology

We utilize the latest CNC technology and machinery to produce parts with exceptional accuracy and efficiency.

3. Skilled Workforce

Our engineers and machinists are highly skilled professionals with years of experience in precision machining. They continuously undergo training to stay updated with industry standards and innovations.

4. Custom Solutions

We understand that every project is unique. Our team works closely with clients to provide tailored solutions that meet specific requirements, ensuring complete satisfaction.

Choosing the Right Materials for CNC Machining

The choice of material plays a critical role in the performance and quality of precision machining CNC parts. Common materials used include:

- Aluminum: Light, strong, and corrosion-resistant, making it ideal for various applications.

- Steel: Offers high strength, durability, and wear resistance.

- Brass: Excellent for parts that require good machinability and corrosion resistance.

- Plastics: Lightweight and versatile, suitable for various non-structural applications.

Understanding the Costs of Precision Machining

While costs can vary greatly depending on several factors, understanding how pricing works can help businesses budget effectively. Key factors affecting the cost of precision machining CNC parts include:

- Material Costs: The type of material used can significantly impact pricing.

- Complexity of Design: More intricate designs typically require more machining time and resources.

- Volume: Larger production runs can reduce the cost per part.

- Technological Capabilities: Advanced machines and technology can influence both quality and price.

Conclusion: The Future of Precision Machining CNC Parts

The future of precision machining CNC parts looks bright, with advancements in technology paving the way for even more innovation. At DeepMould.net, we are committed to staying at the forefront of industry trends, embracing new technologies, and delivering the highest quality parts to our clients. As businesses continue to seek efficiency, precision, and quality, our role as leading metal fabricators will be more crucial than ever.

In conclusion, whether you are in aerospace, automotive, or any other industry requiring precision components, trust in the expertise of DeepMould.net to provide innovative, precision-engineered solutions.